Dr Mahesh Gadekar/ October 28, 2020/ Concrete, Dr Mahesh Gadekar, Geoenvirovision/ 1 comments

Concrete mix design a need of great structure

A sound infrastructure is pride of owner. The important entity of today’s structure is a skeletal that withheld successfully all the loads. Thus, the reinforced concrete is a foundation of the structure. In accordance, a good concrete mix design has a significant value as one of the basic foundations of structure.

Concrete mix design involves a process of preparation of a mix from the ingredients that responsible to produce required strength and durability for the concrete structure. Because every ingredient in the mix consists of different properties. It is not an easy task to create a great concrete mix. It is imperative that, all ingredients be tested to determine their physical properties and the bearing capacity of the project location.

The ingredients to be tested: water, fine aggregate (sand), coarse aggregate, cement, chemical admixtures, and mineral admixture.

The values of the physical properties obtained after testing will be used as the basis for all concrete mix design considerations. This will ensure the structure will be sound and prevent failure of the mix. It is important to note that the ingredients for the mix might vary from one project location to another, so the physical properties must be tested for the requirements specified for each location.

The types of concrete mix characterized by their strength as the normal performance concrete (NPC) and high-performance concrete (HPC). NPC has a performance strength in range of 20 to 40 N/mm2. NPC has a good workability, in case of accurately designed mix proportion. NPC has a performance strength above 40 N/mm2. Usually, HPC preferred to reduce the weight, creep or issues such as permeability and also to increase the durability of concrete. Freshly mixed concrete needs to be plastic or semi-fluid in order to get easily molded.

There are several factors that affects the durability of the concrete mix. Following are the prime factors,

Concrete grade designation: Concrete’s strength measured in N/mm2 or MPa. The grade designation written as M followed by strength at 28 days. e.g. M20 denotes concrete mix of 20 MPa strength at 28 days.

Cement: Various cements are available in market. Cement choice varies depending on usage. The cement should be in fresh condition and should be tested for its performance through laboratory testing.

Aggregates: Concrete mix design required depends upon also the physical properties of the aggregate. They should be tested laboratory for their physical properties to understand the possible small steps to be undertaken at location before mixing. All the aggregates should be quality sized before use.

Water: Typically, water available at or nearby site is utilized for the concrete mix. Any water used for the concrete should ensure quality standard of water. Most of all consumable (potable) water are good for concrete work, still they should be tested before use.

Water to cement ratio: The ratio of water to cement provides the consistency, initial and final setting, soundness of the cement, workability, slump of the concrete and compacting factor. The material mix designer will ensure the correctness of water to cement ratio as per material quality and strength requirements.

Workability: Workability measures the ease of mixing of concrete. The mix should be designed to ensure no segregation, or bleeding. Typically, measure for this is slump of the concrete.

Durability: The durability measures the required strength of concrete grade after 28 days of curing. The test on site will be taken in locality at 7 days and 28 days for cube filled of the same batch.

Further, to ensure the quality of concrete in-situ, non-destructive tests such as Schmidt rebound, UPV used. Also, the actual strength can be tested using core testing.

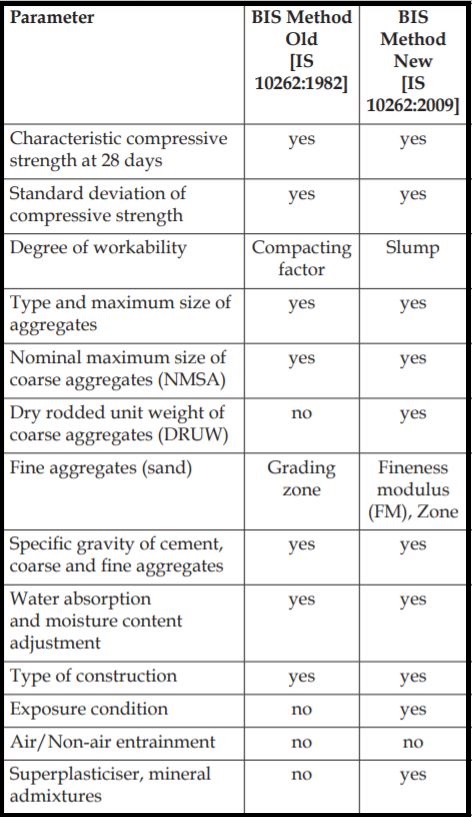

In India, standard code of practice for the design of concrete mix is “IS 10262”. Latest revisions are published in year 2019. The title of the code is “Concrete mix proportioning – guidelines”. The standard was first published in year 1982, subsequently revised in year 2009.

The standard is a second revisions to earlier standards. In brief, following are the changes made in code of practice,

- It includes mix proportioning procedure for high strength concrete such as M65 and above.

- The initial input data to be provided for proportioning a mix made more encompassing, in accordance with provisions of IS 383: 2016 ‘Coarse and fine aggregate in concrete’ use of admixtures, and so on.

- The target mean strength of mix proportioning formula includes a new factor based on grade of concrete. This is to ensure minimum marginal strength between characteristic compressive strength and target compressive strength.

- Standard deviation calculations provided in detail.

- Water-cement ratio and compressive strength at 28 days of concrete has been introduced for several grades and types of cement.

- Several illustrative examples for mix proportioning provided in annexures, such as PPC, OPC with mineral admixtures, High strength concrete (HSC), self-compacting concrete, and mass concrete.

- Guidelines on using or selecting water reducing admixtures provided in annexure.

- Air content in design are considered.

This standard complies with the almost all provisions of IS 456: 2000 ‘Plain and reinforced concrete —Code of practice’. Overall, the concrete proportioning should meet in trial mix to provide required compressive strength, and durability for site conditions and exposures. Additionally, checks for concrete strength and quality can be assessed through the non-destructive testing and core testing. Few photographs can be observed showing concrete mix design trial mixes and testing of concrete before placing and after setting and gaining strength.

I appreciate you sharing this blog. Really looking forward to read more. Want more. Zarah Wainwright Bradly